Testimonal First of all, please accept my warmest thanks for this great engineering masterpiece! I am extremely happy to report that, once completed, this would be the largest automated tsunami gate in the world! And, what is even more important, respecting the strict technical parameters such as the opening time (below 1 second – 0.75 seconds – WOW! J) colleagues in Universities in Japan, Germany and Netherlands – they were impressed! Encore une fois, GROS merci! Ioan NISTOR, PhD, ing., F.CSCE, F.EICProfesseur / ProfessorGénie Civil | Civil Engineering

Cowan Connection

Latest News from Cowan Dynamics

What is an anti-surge valve?

An anti-surge valve is specifically designed and installed to protect the compressor from reaching its surge point. The valve is in the system, in a by-pass that connects the inlet and the outlet of the compressor. In normal operation, this valve remains closed, however, if the surge is detected, it quickly opens to maintain a minimum flow and directs the backflow to the outlet of the compressor to avoid damages. The valve must be completed with controllers that use the suction and discharge pressure and temperatures to determine the flow at which the condition of surge will occur. It is crucial for such valves to be operated by actuators that can achieve extremely fast stroking times, high frequency of operation minimal dead time and minimal overshoot. What is compressor surge? In...

📖 Delayed Coking & Delayed Coker Unit Reference Guide

Coking Refinery Types Delayed Coking Delayed Coking is a refinery unit operation that upgrades the lowest value bottoms material (vacuum resid) from the atmospheric or vacuum distillation column and cracks it to the point that all of the resid is eliminated. This process yields lighter fractions and solid carbon into higher-value products and produces petroleum coke—a coal-like material. During the cracking process, a firing heater with horizontal tubes is used to achieve temperatures ranging from 485 to 505 C (905 to 941 F). Coking in the furnace tubes is, therefore "delayed" until the feed material reaches large coking drums downstream of the heater. You can produce petroleum coke in three physical structures: shot, sponge, or needle. Simply put, a delayed coking unit (DCU) processes...

Maximize flotation cell mineral recovery

In this article you'll learn to maximize mineral recovery in a flotation cell. Dart valves have traditionally been used as level control valves in flotation cells. The dart valve positioning in flotation cells requires high consideration as the goal is to maximize mineral recovery. For this reason a reliable and accurate control valve actuator is crucial. Pneumatic actuators vs electro-hydraulic actuators for dart valve control Traditionally dart valves use pneumatic actuators to control the flotation cell level. However, due to air compression or elasticity, this method of automation can cause problems in accurate and efficient level control. The thrust due to the pressures at the bottom of the cell acts against...

What are electro-hydraulic actuators?

Electro-hydraulic actuators are devices that operate a valve through pressurized hydraulic fluid, however, their main source of energy is solely electrical. The electrical power supplied is used to energise a motor that runs a hydraulic pump which then supplies the pressurized fluid to operate a hydraulic actuator which controls the valve. The complete system is self-contained, eliminating the need for a separate hydraulic power unit, simplifying system construction and improving safety and reliability. A self-contained electrohydraulic actuator can be used with linear or rotary valves, the need for its use will depend on the requirements of the application. These devices are ideal for operating valves that need large torques or thrusts, or where fail-safe systems or high operating...

Electrohydraulic Actuator vs. Electric Actuator

Due to their design, electric actuators have limitations in terms of output torques, duty cycle, failure modes, speeds, and vibration resistance. In severe applications where valves with high torque or thrust must be operated quickly, such as emergency shutdown valves (ESDV), electric actuators have limitations because they can only store a certain amount of energy to operate the valve in the event of a power failure, which eliminates them as options in many emergency shutdown valve applications. In the same way, because they are operated directly by an electric motor, they present limitations in the operating speed; on one hand, the demand increases significantly as the speed increases and on the other hand, their operating speeds are constant since they depend on the RPMs of the...

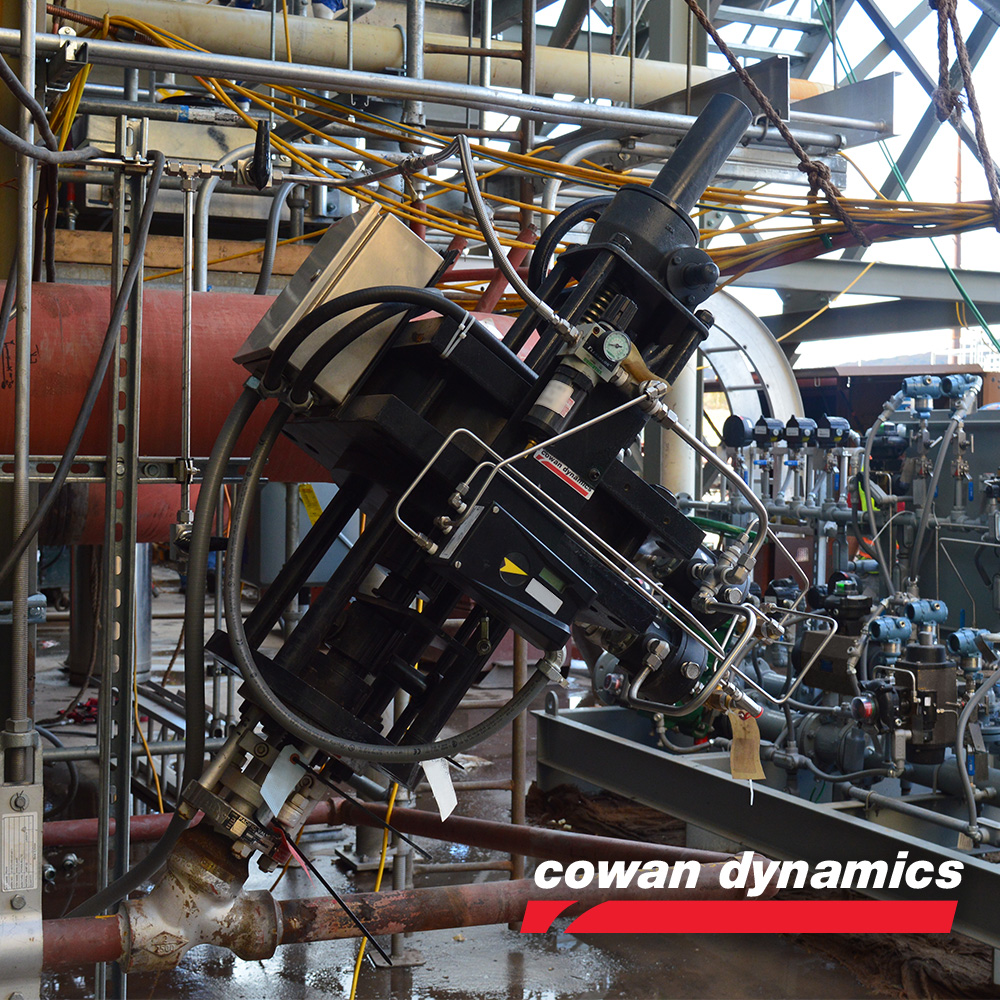

Featured Valve Automation Actuators

A Series Feature

Designed and engineered for severe-service applications, the A Series bore sizes range from 4” to a whopping 42” diameter. We also offer a wide range of automation options.

AS Series Feature

Next-generation “compact” model provides a shorter and lighter canister for installations where space is a premium.

ML Series Feature

Our ML Series Double-Acting Hydraulic Valve Actuators are designed to suit a wide range of applications; from commodity to severe-service extremes.