Cowan Dynamics

This article has been reviewed by Cowan Dynamics Application Engineering team. Contact Us and our application engineers will assist you with your application.

A thank you to Bernd Schneider (Industry Manager Energy – Balluff GmbH Germany) for this weeks blog post on sensors for arctic conditions.

The climatic conditions in the arctic are characterized by cold winters and short summers. There is a large variability in climate and weather: Some regions face permafrost and are ice covered year-round with temperatures down to -40°C / -40°F (and lower), other land areas face the extremes of solar radiation up to +30°C / +86°F in summer.

As oil and gas exploration moves into arctic areas, the need grows for sensors designed to deal with the extreme conditions and to perform reliably over their whole life cycle.

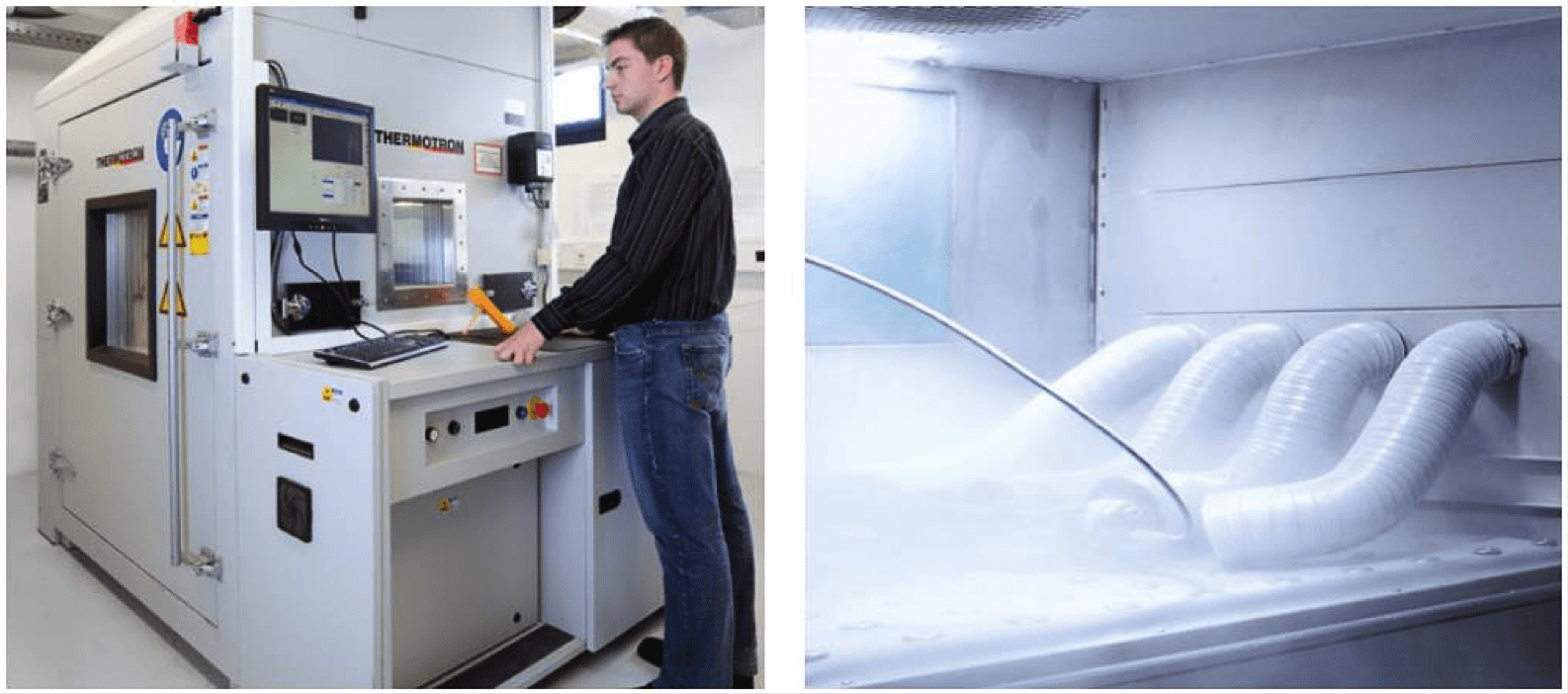

One option is the implementation of a Highly Accelerated Life Test (abbreviation HALT) in the development process. The basic idea of HALT is the accelerated aging of electronic products (including sealing gaskets, potting compound, housing etc.) with the aim of detecting their possible weak spots as early as possible and to correct them at the development stage.

The item under test is subjected to higher and higher thermal and mechanical stress in order to cause failures. The limits where the product will fail functionally or be destroyed are determined in order to push these limits as far out as possible, and so achieve a higher reliability for the product.

The HALT procedure – in brief:

- Analysis of weaknesses already known, definition of failure criteria, establishing the stress factors

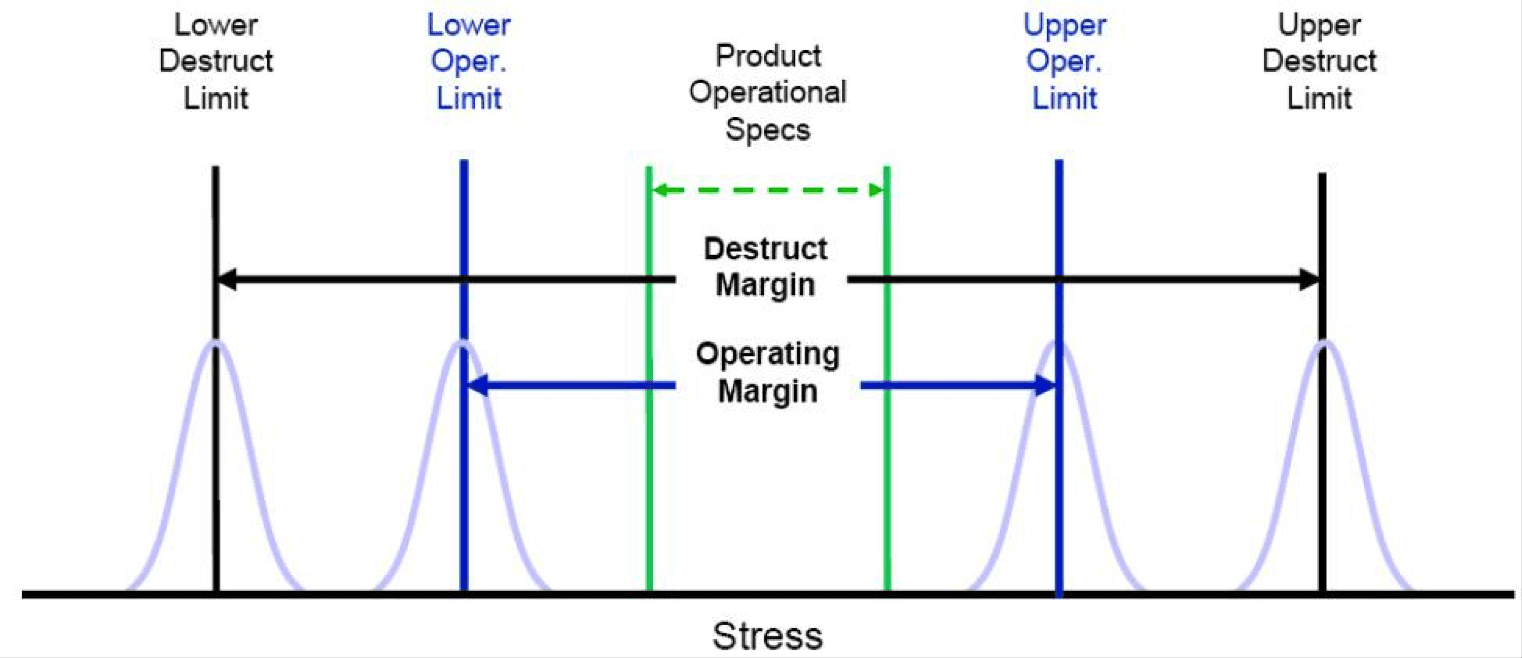

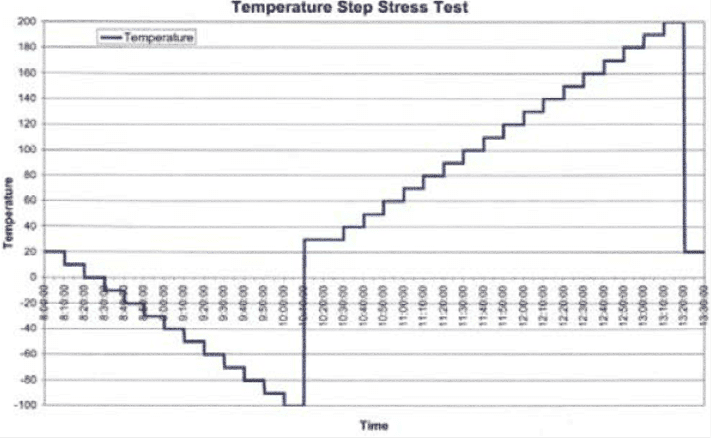

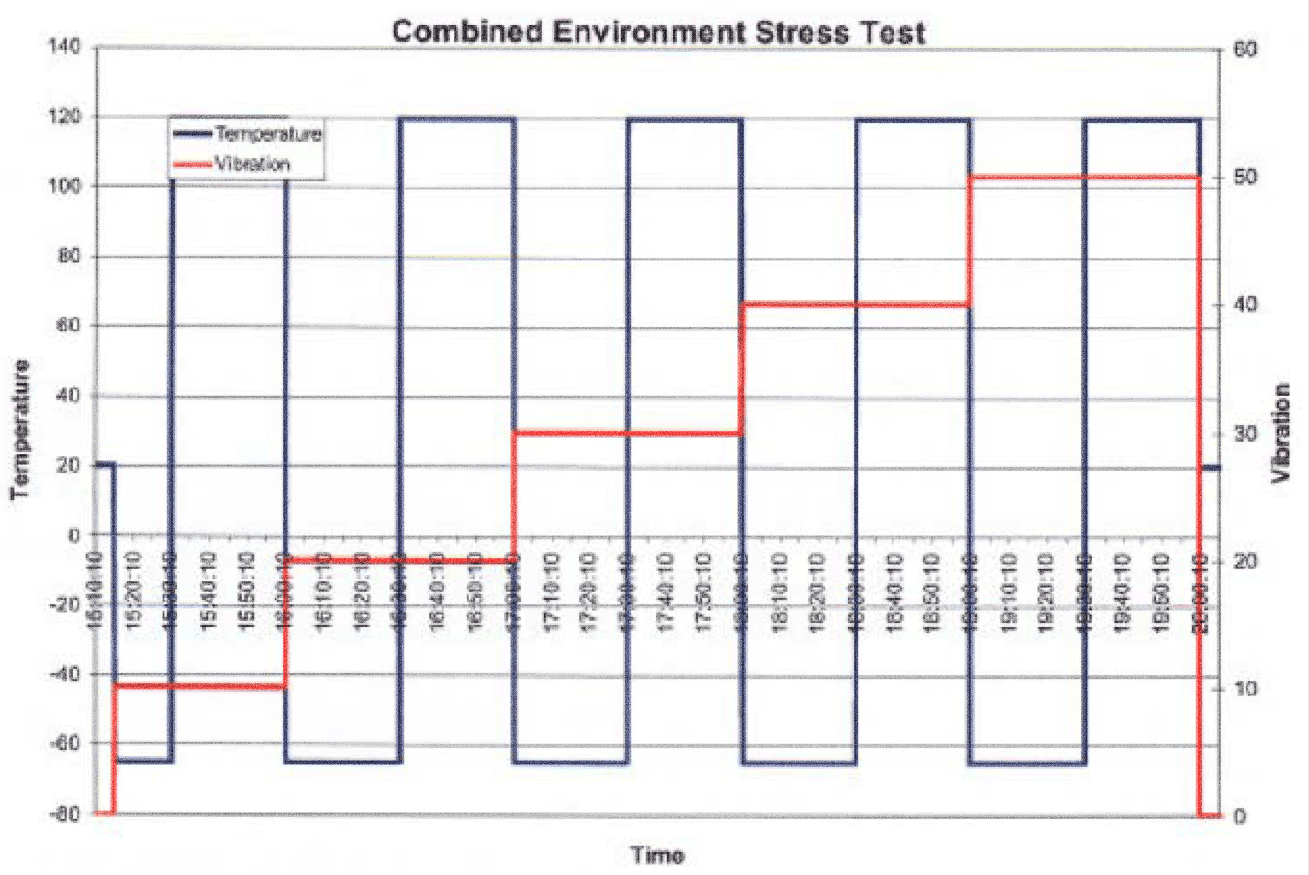

- Stressing the test specimen beyond the specification to find the “upper and lower operating limits”, and the “upper and lower destruct limit” for temperature, rapid change of temperature, vibration, combined vibration and temperature stress

- Determination of the causes of failure

- Devising a solution to eliminate the weaknesses

- Repeating of steps b) to c)

In contrast to other environmental tests, HALT is not qualification testing according to specific technical standards (as ISO/IEC etc.), but it applies stimuli to the items under test until they fail, so that weak spots will be revealed. A HALT test is not an exam you can pass!

But if sensors are implemented into more complex automation systems that will be operated in remote areas, this method may help to prevent major faults in the field and is therefore also used in the aircraft and automotive industry.