AS SeriesSpring-Return Pneumatic Valve Actuator

Next generation “compact” model provides a shorter and lighter canister for installations where space is a premium. SIL-3 Capable. Thrust up to 72,000 lbs.

Specifications

Specification Overview

| Thrust | up to 72,000 lbs |

|---|---|

| Bore size | 6”- 42” |

| Configuration | Single-Stage and Tandem |

| Stroke Range | Up to 24” |

| Pressure Rating | 150 psi |

| Rod Size | 1” to 5 1/2 “ |

| Welding Certified to | CSA 47.1 Division 2 |

| Fail Modes | Fail-Close or Fail-Open |

| Rating | SIL-3 Capable |

| Options | Compact Model Available |

Material Overview

| Material Breakdown | Standard | Corrosion Resistant |

|---|---|---|

| Head & Cap | A-36 hot rolled steel | 316 |

| Barrel (Air-Stage) | Composite | Composite |

| Piston 6-8″ | Aluminum | Aluminum |

| Piston 10″ & above | Mild Steel | Mild Steel |

| Piston Rod | 1045 | 316 |

| Gland | SAE 660 | Delrin |

| Canister | Steel | 316 |

| Spring | High Strength Steel | High Strength Steel |

| Tie Rod 6″-10″ | C12L14 | 316 |

| Tie Rod 12″ & above | ASTM A311B | 17-4 |

| High Temp | -10°C (14°F) ~ 200°C (392°F) |

|---|---|

| Standard Temp | -20°C (-4°F) ~ 104°C (219°F) |

| Low Temp | -54°C (-65°F) ~ 90°C (194°F) |

Highlights

The AS Series Spring-Return Pneumatic Valve Actuator’s SIL 3 capable rating is designed to provide reliable actuation solutions in critical applications without compromising the facilities Safety Instrumented Systems (SIS – compliant with IEC 61511/ISA 84).

- Choose from a full range of readily available dimensional sizes and thrusts

- Reduce design and developmental costs

- Faster, simpler selection process improves your project planning and turnaround on proposals, feasibility studies, etc.

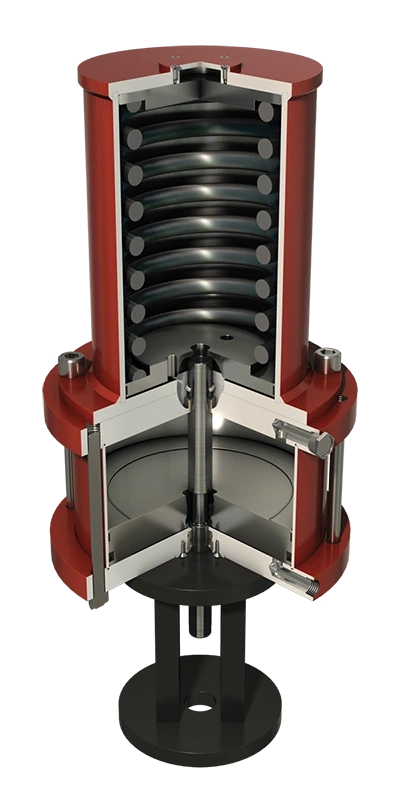

- Springs are pre-compressed and factory-sealed inside a welded steel canister: no extended tie-rods required!

- Modular Canisters are easily and safely removed for simple in-field servicing of actuator piston seals

Design & Materials

Click on the (+) Icons to see more details.

Flange Cover | Allows access to jam-nut to quickly and safely remove the canister for in-field service; Access for manual override available as an option

Spring | Available in thrust up to 72,000 lbs.; Ground Flat for stability

Self-Contained Spring Canister | Spring is pre-compressed and factory-sealed inside a welded steel canister: no extended tie-rods required; Allows safe in-field service of piston packings, rod seals and bushings

Barrel Seals | Nitrile O-ring standard; High or low temp optional

Wear-Band | BZ-PTFE for high temp version

Piston Packing | Nitrile U Cups are standard; High and low temp optional

Pedestal Mount | Carbon steel interface; Base plate is machined to suit valve requirement; Standard with dual adjustable stops; Optional accessories: Open and close limit switches; Lockouts; Travel stops

AS Series Applications

Industries trust us to provide state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Datasheets & Videos

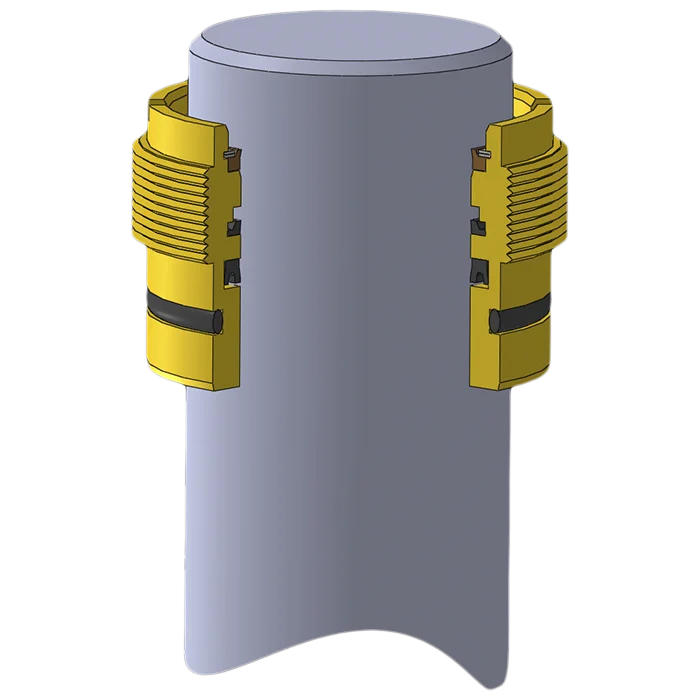

Gland Seals

Triple-seal gland with dual wipers. Rugged metallic scraper and urethane double-acting wiper deflect contamination away from the rod seal for long service life.

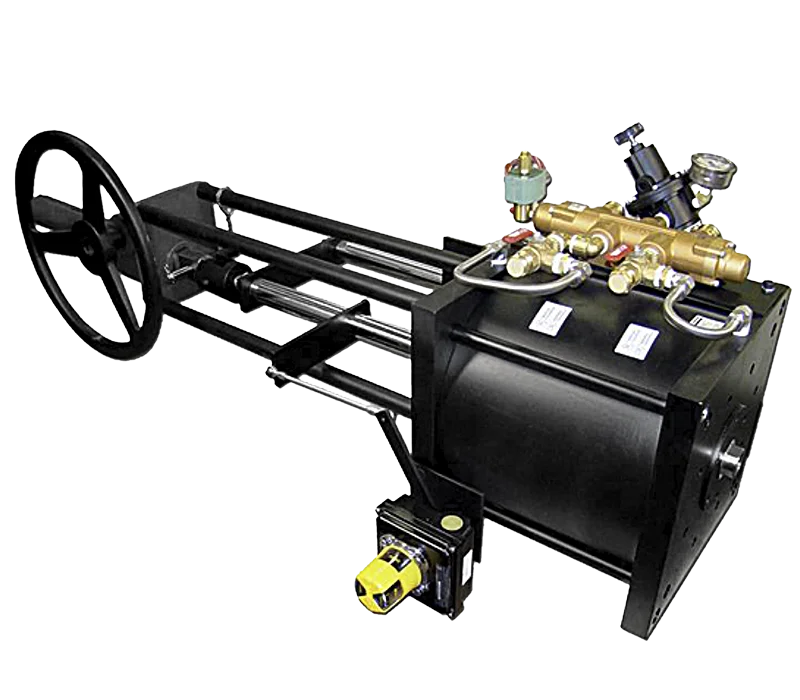

Hydraulic manual override with indicator

Manual override options are available.

Screwjack with handwheel

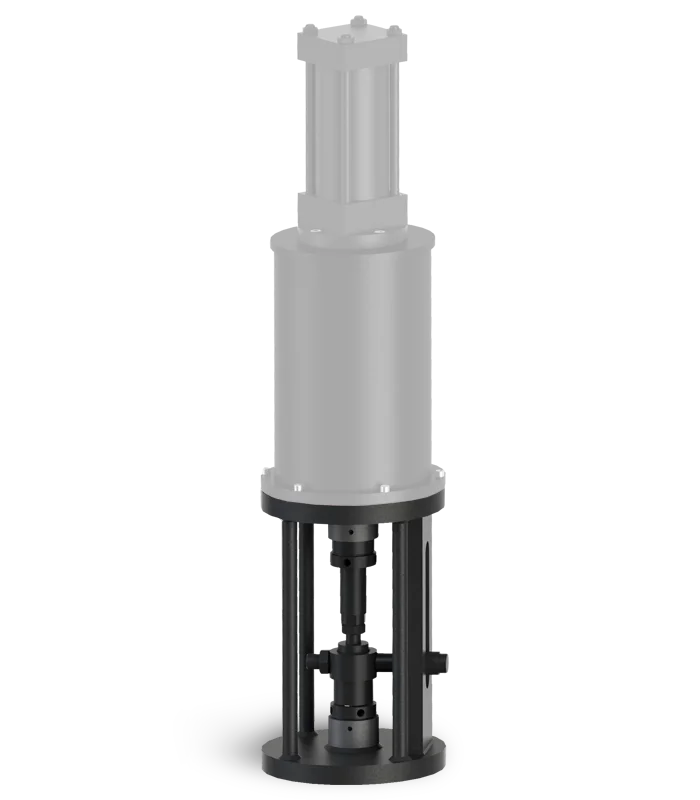

ISO, MSS & Customized Patterns Available

Cowan valve mounting kits can be designed for any linear valve. Mounting kits available in steel and stainless steel construction.

Maintains constant alignment between valve stem and cylinder piston-rod. Compatible with rotary type switch boxes and beacons.

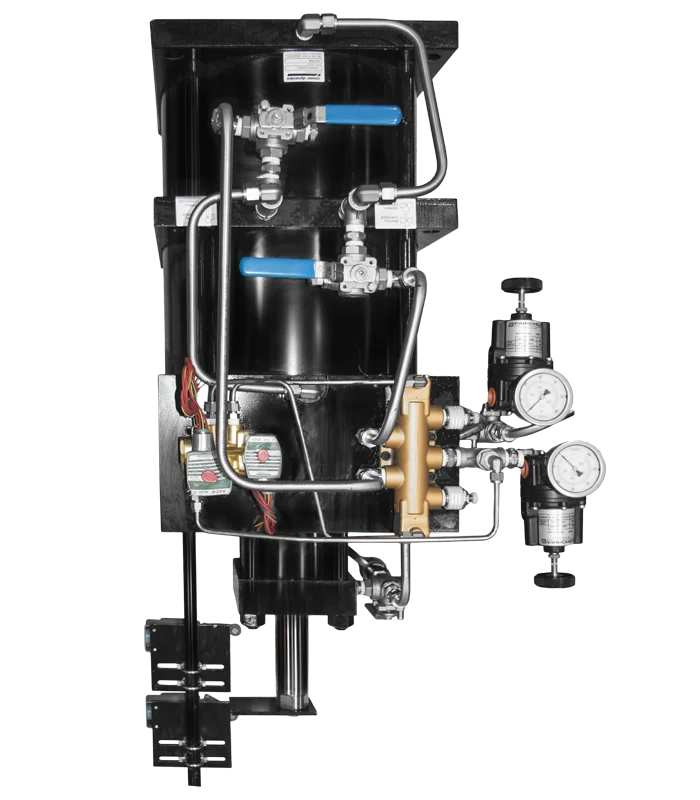

Automation Packages

Solenoid Valves

Pilot Valves

Quick Exhausts

Positioners

Limit switches and position sensors

Field-adjustable for open and close indication.

Analog and digital feedback