CGO SeriesGas/Oil Rotary Actuator

400,000 cycles Without Loss of Precision | Effective Diaphragm Area: up to 217 in2| Thrust: up to 13,000 lbs

Specifications

Specification Overview

| Explosion-Proof Level | Ex d IIB T4 (Ex d IIC T6 available) |

|---|---|

| Ingress Protection Level | IP 65 (IP 68 available) |

| Safety Integrity Level | SIL 2 |

| Air Supply Pressure | 5 – 150 Bar |

| Suitable for Rotary (Quarter-Turn) valves | Linear design also available. |

| Nitrogen Gas Application | High-sulfur natural gas and oil pipelines can use nitrogen gas as a power supply. With the bubble tight pneumatic control manifold, the nitrogen bottles only need to be replaced once or twice a year. |

Performance Overview

| Actuator Model | 03 | 06 | 09 | 15 | 30 | 60 | 100 | 200 | 300 |

|---|---|---|---|---|---|---|---|---|---|

Maximum Output Torque (in-lb) | 39,828 | 79,657 | 119,485 | 199,142 | 398,284 | 796,567 | 1,327,612 | 2,655,224 | 3,982,836 |

| Item | Electronic Line Break Protection | Mechanical Line Break Protection |

|---|---|---|

| Components | Controller, transmitter, solenoid valve | Rate tank, time delay valves, differential pilot |

| Precision | High, 0.1% | Low, more than 0.1% |

| Setting & Testing | Easy and measurable | Very difficult and unmeasurable, special tools required |

| Even Record | Yes, query-able and traceable | No, not query-able and untraceable |

| Power Supply | Direct 24VDC, Solar + battery (optional) Internal battery (optional) | N/A |

Highlights

Power requirement of 0.8W

Supports a low temperature display down to -40°C

Records high-pressure, low-pressure and pressure drop rate extremes.

Analyses line pressure recorded data to improve pipeline pressure fluctuation predictions at the CGO location.

Local communication: USB, with PC software

Remote communication: RS485, with standard MODBUS-RTU protocol.

Design & Materials

Click on the (+) Icons to see more details.

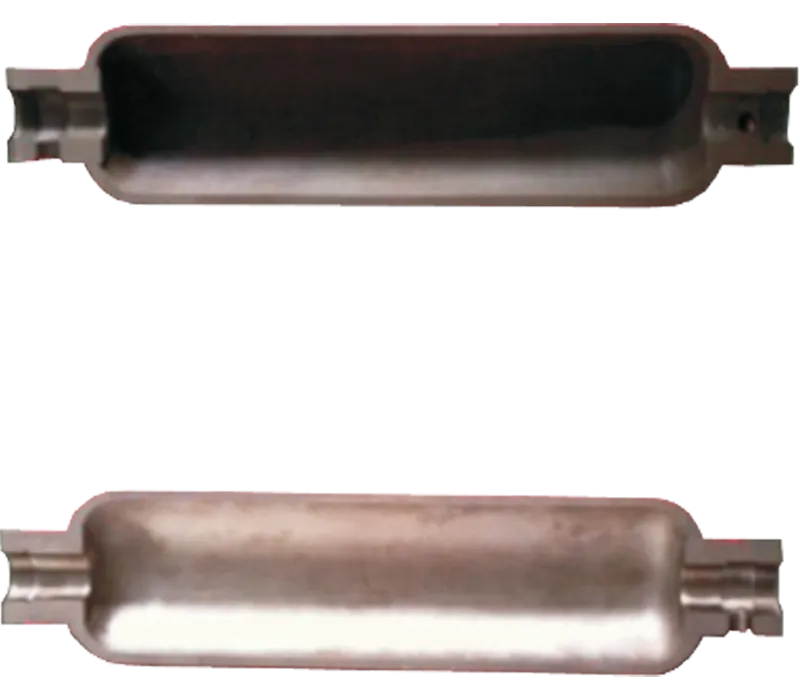

Pressure Vessels

- Complies with ASME VIII or GB150.

- Heat shrink technology.

- Nickel plated inside – eliminates corrosion and contamination, prolonging service life.

Torque Limiter

- Ensures reliable operating of the valve while preventing damage to the valve stem and actuator.

Pneumatic Control Manifold

- Zero leakage within 5 to 150 Bar, especially suitable for nitrogen gas application.

- The specifically designed muffler is used for venting noise reduction.

- Solenoid valves are SIL 3 capable.

Hydraulic Hand Pump

- Integrated with a four-position directional control valve for open, closed, automatic and bypassed operation shifting.

- Hydraulic outlet is consistent for every stroke operation.

Scotch-Yoke Mechanism

- Quarter turn stroke: -5° to 95° adjustable.

- The cylinder features dual seals to guarantee zero leakage.

- Symmetric and canted yokes are available to satisfy various valve torque profiles.

CGO Series Applications

Oil and Gas

In oil and gas applications, the CGO Series oil/gas rotary actuator ensures precise control over valve movements, facilitating efficient flow regulation in pipelines, while also enhancing safety and reliability in critical operations.

Chemical Processing

In chemical processing, the versatility of the CGO Series oil/gas rotary actuator enables seamless adjustment of valves, ensuring optimal conditions for chemical reactions and material flow, thereby boosting process efficiency and product quality.

Mining

For mining operations, the CGO Series oil/gas rotary actuator plays a pivotal role in controlling valves and dampers, enhancing the safety and efficiency of material handling processes, while also minimizing downtime and maintenance costs.

Power Generation

In power generation, the CGO Series oil/gas rotary actuator of a scotch yoke actuator enables accurate regulation of valves in steam turbines and other power plant equipment, contributing to enhanced operational efficiency and reliability.

Water Treatment

Water treatment facilities rely on the CGO Series gas/oil rotary actuator to precisely manage valve operations, ensuring effective filtration, disinfection, and distribution processes, thereby maintaining water quality and safety standards.

Manufacturing

In manufacturing environments, the CGO Series gas/oil rotary actuator machinery operations with precision, enhancing production efficiency and consistency while reducing manual labor and operational errors.

Datasheets & Videos

CGO Gas/Oil Rotary Actuator. Extreme temperature laboratory simulation.

Arctic installation