SIL 3 Actuators

The SIL 3 capable rating is designed to provide our customers reliable actuation solutions in critical applications without compromising their Safety Instrumented Systems (SIS – compliant with IEC 61511/ISA 84).

The SIL 3 capable rating was achieved by certifying the products to IEC 61508 and was obtained from Exida Certification Services after passing rigorous Failure Mode Effects Diagnostic Analysis (FMEDA).

SIL 3 Linear & Rotary Actuator Lineup

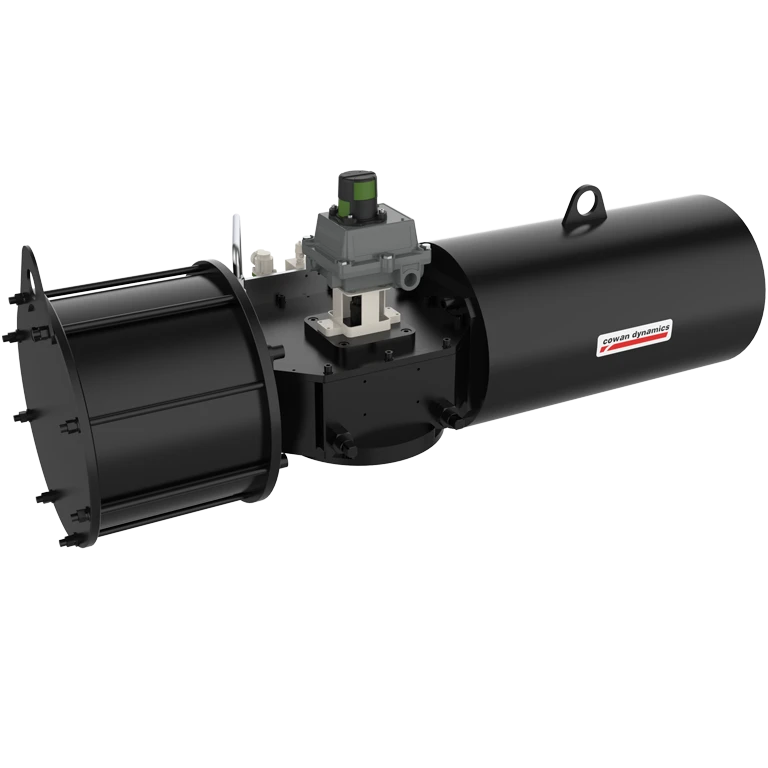

E2H-ESD

Electro-hydraulic ESD Actuator

The E2H-ESD is designed for Emergency Shutoff Valves and features a completely modular design consisting of the following modules: hydraulic power unit, hydraulic cylinder, scotch yoke mechanism, spring canister, and control panel for local and remote operation.

- Torque up to 3,000,000 in-lbs

- SIL-3 Capable (pending)

- Hydraulic Manual Override

- Operating Temp. -50ºC to 40ºC

CSY Series

Pneumatic Rotary Actuator

The CSY Pneumatic Rotary Actuator modular design that allows customization to fit specific needs. Bi-directional travel stop allows an adjustable stroke range of 80 degrees to 100 degrees. NAMUR mounting allows standardization of mounting hardware for a wide range of shaft-driven accessories.

- Double-Acting or Spring-Return

- Torques up to 2,500,000 in-lbs

- Operating Pressure: 40 – 100 PSIG

- Low Temp. -40ºC to 80ºC

- Standard Temp. -20ºC to 80ºC

- High Temp. -20ºC to 120ºC

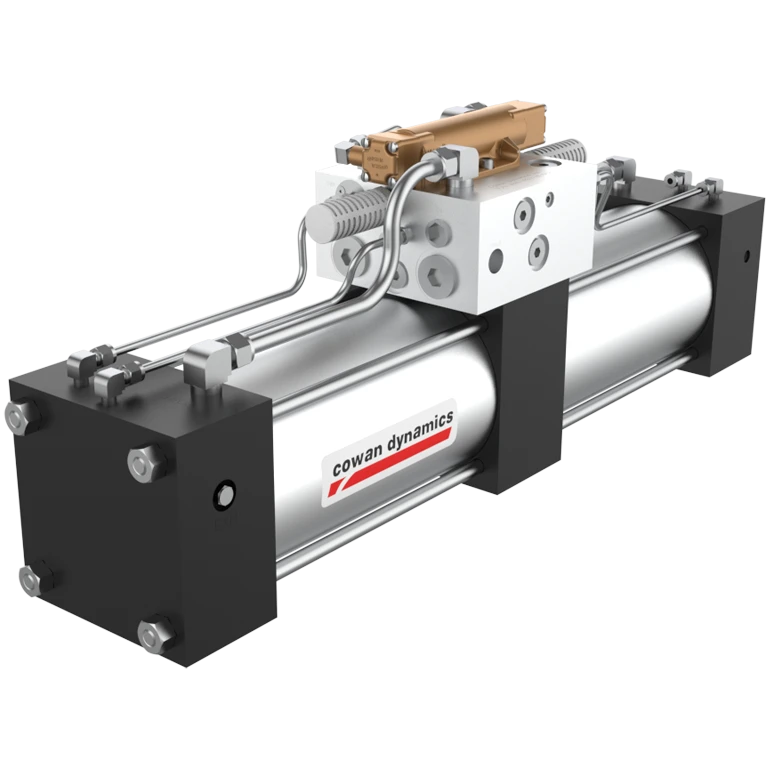

ML Series

Double-Acting Hydraulic Valve Actuator

Delivering thrust up to 1,500,000 lbs and SIL-3 Capable. Our double-acting hydraulic valve actuators are designed to suit a wide range of applications; from commodity to severe-service extremes.

- Bore Size: 1 1/2″ to 24″

- Configuration: Single-Stage

- Stroke Range: Up to 144″

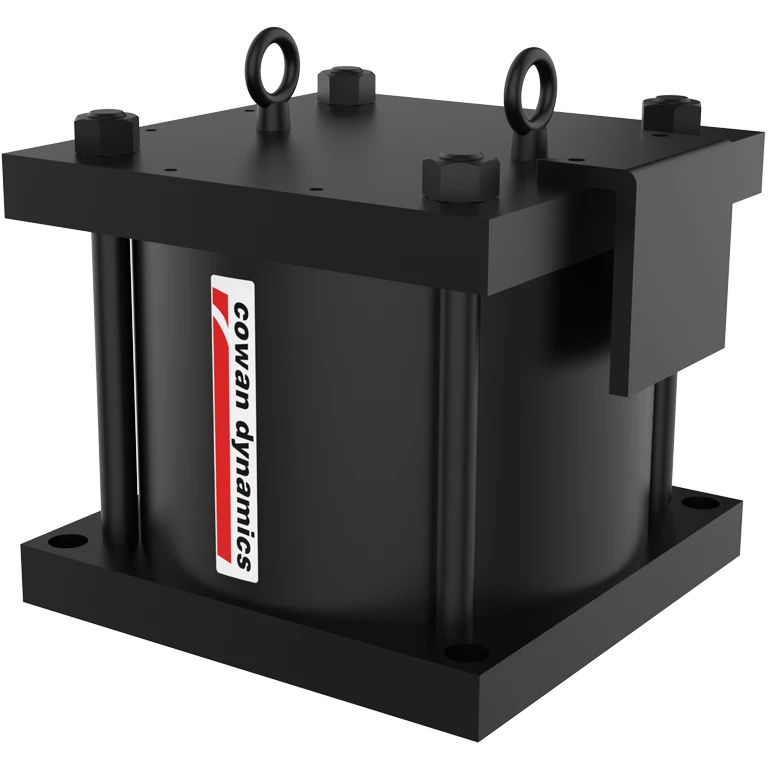

MS Series

Spring-Return Hydraulic Actuator

SIL 3 capable. Custom dimensional sizes and thrusts available. Springs are pre-compressed and seals in a factory-installed canister. Available in fail-open or fail-close.

- Thrust: up to 72,000 lbs

- Bore Size: 1 1/2″ – 14″

- Rod Size: 1″ – 7″

- Stroke Range: Up to 24″

A Series

Double-Acting Valve Actuator

The Double-Acting Valve Actuator comes in a dual or triple seal gland with a high-strength carbon fibre barrel. Bronze/Teflon piston wear band and a removable cartridge bushing. Made-to-order stroke lengths. Valve mounting kits available

- Bore size: 4″ to 42″

- Piston rod diameter: 1″ to 5 1/2″

- Available in single-acting and double-acting

AS Series

Spring-Return Valve Actuator

Available in fail-close or fail-open. Standard offering – no custom design required. The Spring-Return Valve Actuator is available in a full range of dimensional sizes and thrusts. Springs are pre-compressed and sealed in a factory-installed canister. Canisters are easily and safely removed for in-field servicing.

- Valve Size: 2” to 10”

- Thrust: up to 72,000 lbs

- Designed for the most demanding applications where position control is essential

AT Series

Pneumatic Modulating Valve Actuator

The Pneumatic Control Valve Actuator features a compact design with a self-contained transducer. No exposed transducer or clumsy linkage arms. Modular transducer for easy installation. Switchable analog or digital output. Dual or triple seal gland. High-strength carbon fibre barrel. Made-to-order stroke lengths. Valve mounting kits available

- Bore size: 4″ to 42″

- Piston rod diameter: 1″ to 5 1/2″

- Stroke: Up to 144″

- Single and double-acting

- Fail-Open, Fail-Close

AT Series

Dart Valve Actuator

The Dart Valve Actuator features a modular transducer for easy installation. Switchable analog or digital output. Dual or triple seal gland. High-strength carbon fibre barrel. Made-to-order stroke lengths. Vibration resistance up to 10Gs at 2000Hz.

- Thrusts up to 55,000 lbs

- US & CAN Patents

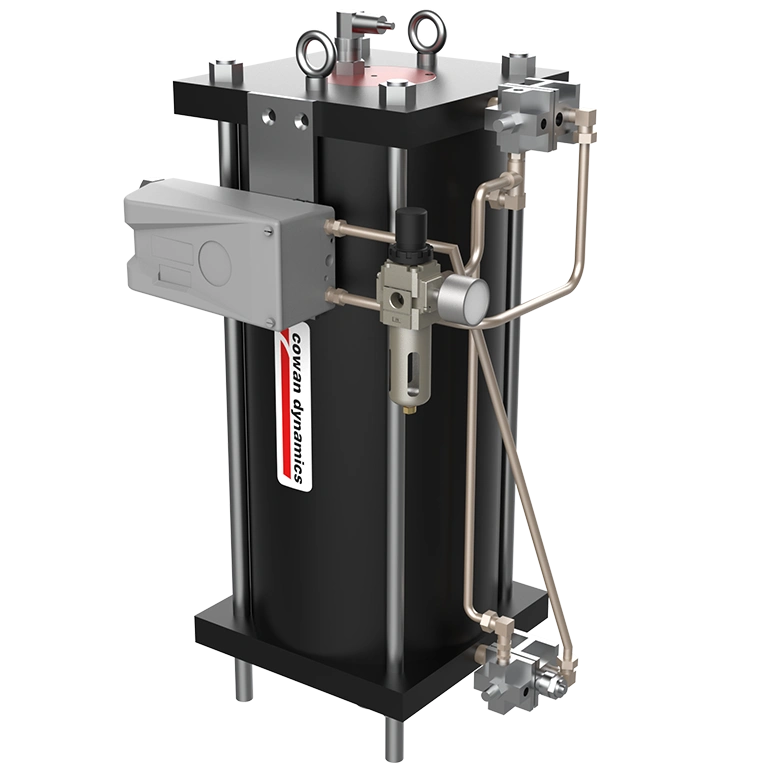

Air to Air Booster

Dual-Stage High-Output Pneumatic Booster

The Pneumatic Booster consists of a basic system plus an air to air booster, Cowan’s boosted air systems are designed for applications in which the available air pressure is too low and where space for additional air tanks is limited.

- Bore diameter: 6″

- Rod diameter: 5″

- Stroke: 12″

SIL 3 Capable Actuator Applications

Cowan offers a variety of SIL 3 capable linear and rotary (quarter turn) valve actuators that can be customized to fit the customer’s requirements for various markets and applications.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems, like our dart valve automation products.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.