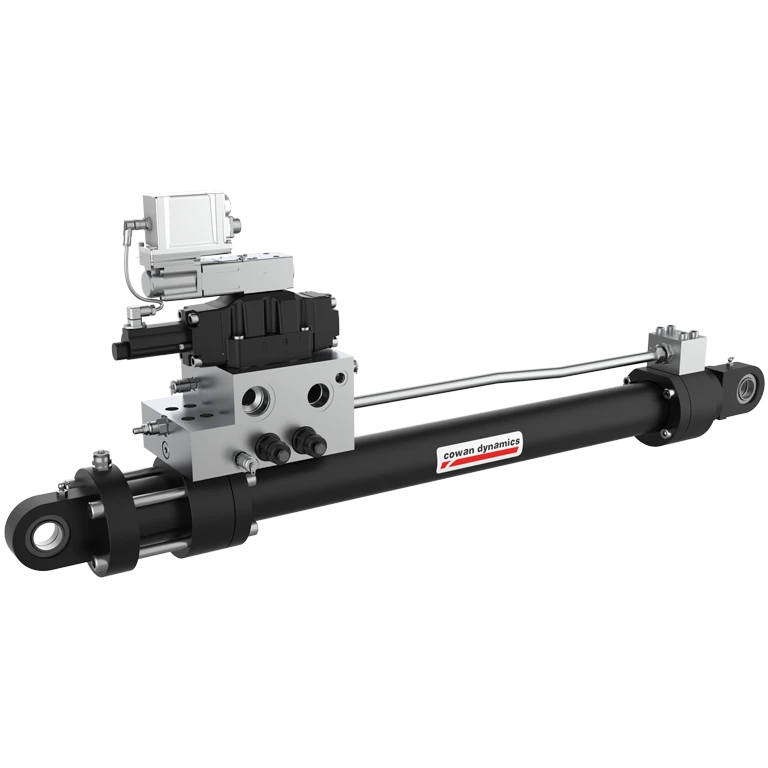

R SeriesHydraulic Mill-Type Cylinder

Bore Sizes: 4″ – 16″ | Available in pressure ratings of 300 Bar (Metric), 3000 PSI and 5000 PSI

Specifications

Specification Overview

| R3 – 3000 psi | Bore Size: 4” to 16” | Piston Rod Diameter: 2” to 10” |

|---|---|

| R5 – 5000 psi | Bore Size: 4” to 16” | Piston Rod Diameter: 2” to 10” |

| RM – Metric Cylinder: 300 bar | Bore Size: 40mm to 200mm | Piston Rod Diameter: 22mm to 140mm |

Material Overview

| Material Breakdown | STANDARD |

|---|---|

| Head & Cap | Machined Steel |

| Flange | Machined Steel |

| Barrel | Seamless Steel Tubing Honed ID *Optional Chrome Plating available |

| Barrel Seal | Nitrile O-Ring |

| Piston | Ductile Iron |

| Piston rod | Steel SAE 1045 |

| Gland | SAE 660 Bronze |

| Tie Rod | Stress-proof Steel |

| High Temp | -29°C (-20°F) ~ 205°C (401°F) |

|---|---|

| Standard Temp | -50°C (-58°F) ~ 105°C (221°F) |

| Low Temp | -54°C (-65°F) ~ 60°C (140°F) |

Highlights

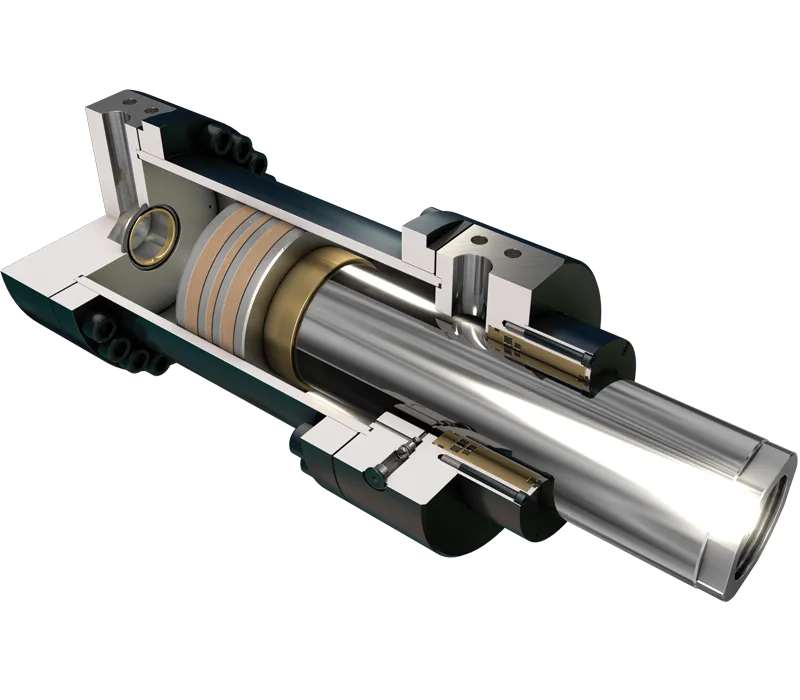

Design & Materials

Click on the (+) Icons to see more details.

1st Rod Seal | PTFE - Low friction and long service life; Protects secondary seal from pressure spikes; Allows a fine film of oil to pass ensuring the necessary lubrication of the secondary seal; Geometry designed to vent pressure from the reverse side - to reduce possibility of pressure trap between seals; Acts as an internal wiper to protect secondary seal from internal contaminants

2nd Rod Seal | PTFE - Low friction; Excellent low-pressure seal ability, long service life

Bronze Teflon Wiper | Double-acting wiper ensures the best sealing performance

Metallic Rod Scraper | (Standard) Rugged scraper deflects contamination away from the rod seals for long service life

Piston Rod | Steel SAE 1045 Ground, hard chrome-plated & polished 17 - 4 PH; stainless steel available as an option

Gland Retainer

Gland Bushing | Cartridge-type AL - bronze

Check Valve & Cushion Valve | Fully retained for safety

Cushion Plunger | Floating cushion plunger provides maximum cushioning effect combined with a quick start for optimum performance

High Load Piston Seal

High Strength Nylon Wear Ring (2X) | BZ-PTFE for high temp version

Cap Screw | Grade 8

Sae Code 62 | Flange ports are standard; BSPP, SAE, NPT also available

Cap | Machined steel

Barrel | Seamless steel tubing, honed & polished to minimize friction

R3

R5

RM

R Series Applications

Industries trust us to provide state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Datasheets & Videos

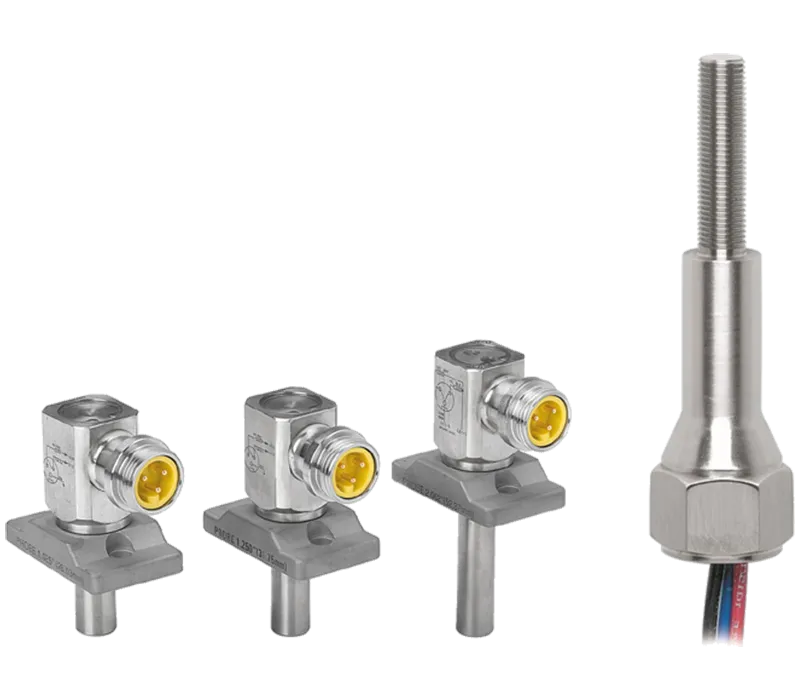

Limit Switches

Mechanical Limit Switch SPDT, for Open & Close Indication. Inductive switches also available. Solid State, Reed and inductive type also available. Specify brand and part number.

Available in 316 Stainless Construction

For corrosive applications. Includes attachments such as Rod clevis and Eye brackets.

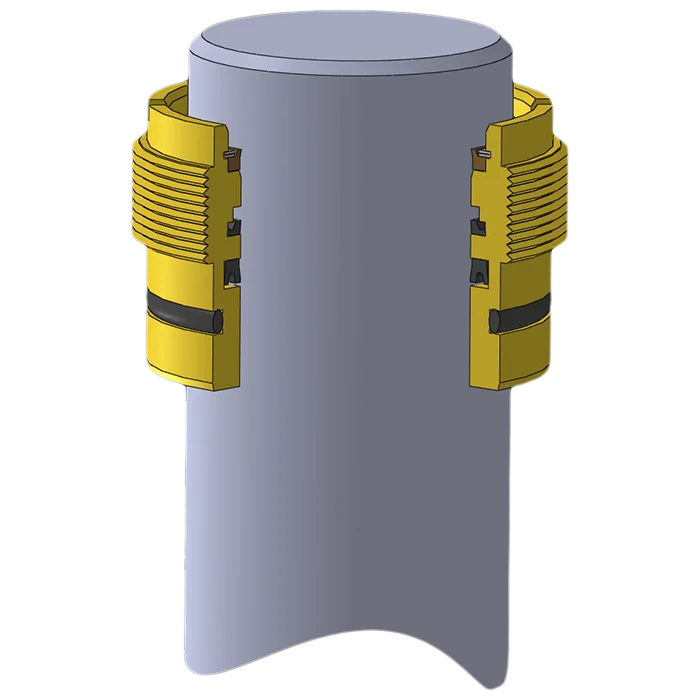

GT3 Gland for Harsh Environments

Triple-seal gland with dual wipers. Rugged metallic scraper and urethane double-acting wiper deflect contamination away from the rod seal for long service life.

Balluff LDT

Optional Balluff LDT for continuous position feedback. 4-20mA, 0-10V and digital outputs available.

Improving the control of the production of steel plates on a Duo rolling mill.