E2H SeriesElectro-Hydraulic Actuator

Compact. Simple. Versatile. Delivering thrust up to 500,000 Lbf and equipped with an energy efficient motor design for linear control valve automation.

Specifications

Overview

| Thrust | Thrust up to 500,000 Lbf |

|---|---|

| Close Thrust | 4,416 – 282,600 lbs |

| Open Thrust | 2,453 – 223,234 lbs |

| Bore Size | 1 1⁄2 ” to 12″ |

| Duty Cycle | 100% |

| Deadband | Adjustable down to 0.1% of stroke |

| Valve Operating Mode | On/Off or Modulating Service |

| Fail Modes | Fail Last, Fail Close or Fail Open |

| Emergency Shutdown | ESD Capable |

| Power Consumption | Very low power consumption – lock in place |

| Override Feature | Hydraulic Manual Override Available |

Hazardous Area Classification

| CSA CI1,Div1,Gr C&D |

|---|

| CSA CI1,Div2,Gr A,B,C&D |

| ATEX, II 3G EEx nA II T3 -40°C ≤ Ta ≤ 65°C |

| ATEX, II 3G EEx nA II T3 -40°C ≤ Ta ≤ 65°C, Tamb ≤ 65°C |

Power Supply Voltage

| 240VAC | 1 Phase | 60 HZ |

|---|---|---|

| 115VAC | 1 Phase | 50 HZ |

| 460VAC | 3 Phase | 60 HZ |

| 575VAC | 3 Phase | 60 HZ |

Environmental Protection Rating

| Nema 4/IP66 | Standard |

|---|---|

| Nema 4x/IP66 | Corrosion Resistant |

HMI

| HMI | Multi Color Touch Screen |

|---|---|

| No HMI | Push buttons / lights- Standard |

Fail System

| Power Fail | With Accumulator |

|---|---|

| With Spring |

Control Panel

| Installed on the actuator | Standard |

|---|---|

| Installed Remote | Optional |

Manual Override

| Optional | Hydraulic hand pump |

|---|

Operational Temperature Ratings

| Standard | (-20C to +40C) |

|---|---|

| High | (-20C to +55C) |

| Low | (-50C to +40C) |

| Standard HMI | (0C to +40C) |

| Low Temp HMI | (-30C to +40C) |

Highlights

All in one design. No need for a separate hydraulic power unit and hoses.

Large, easy to use touch screen for quick setup and operation.

System records position and time data for valve performance analysis.

Initiate PST from touch screen or remotely.

Can be mounted in horizontal valve stem applications.

Remote Diagnostics and Trouble-Shooting by Cowan* (*direct VPN connection required)

Design & Materials

Click on the (+) Icons to see more details.

Compact Design | All in one design. No need for separate hydraulic power unit and hoses.

Easy To Use Display | The large, easy to use touch screen display makes it easy for quick setup and operation. The software provides logging of real-time valve performance for analysis.

Versatile Modes | The E2H provides Fail Last, Fail Close, and Fail Open modes. It also has the ability to be mounted in horizontal and vertical positions.

Linear Valve Actuator | The linear valve actuator offers up to 500,000 Lbf of Thrust.

E2H Series Applications

The E2H Series electro-hydraulic actuator provides state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Enhancing oil and gas processes with E2H Series electro-hydraulic actuators, ensuring precise flow regulation for optimal performance and reliability.

Chemical Processing

Optimizing chemical processing with E2H Series electro-hydraulic actuators, enabling precise adjustment of flow for enhanced product quality and efficiency.

Mining

Improving mining and mineral processing efficiency withE2H Series electro-hydraulic actuators, facilitating precise control over slurry flow rates for optimized extraction and resource utilization.

Power Generation

Maximizing power generation efficiency with E2H Series electro-hydraulic actuators, enabling precise adjustment of steam flow for optimal turbine performance and energy output.

Water Treatment

The precise flow control and continuous modulation capacity of the E2H series allow the optimization of the water treatment operations.

Manufacturing

Boosting manufacturing productivity the E2H Series electro-hydraulic actuator, facilitating precise control over material flow for optimized production processes and quality outputs.

Datasheets & Videos

The E2H Series is an all-in-one design for linear control valve automation. No need for separate & bulky hydraulic power unit and hoses.

The E2H, Electro-hydraulic Actuator for linear valve automation packs high performance into the smallest possible installation envelope for linear valve actuating applications. All hydraulic components and sensors are integrated into a single compact manifold block that also houses the linear actuator and integral oil reservoir.

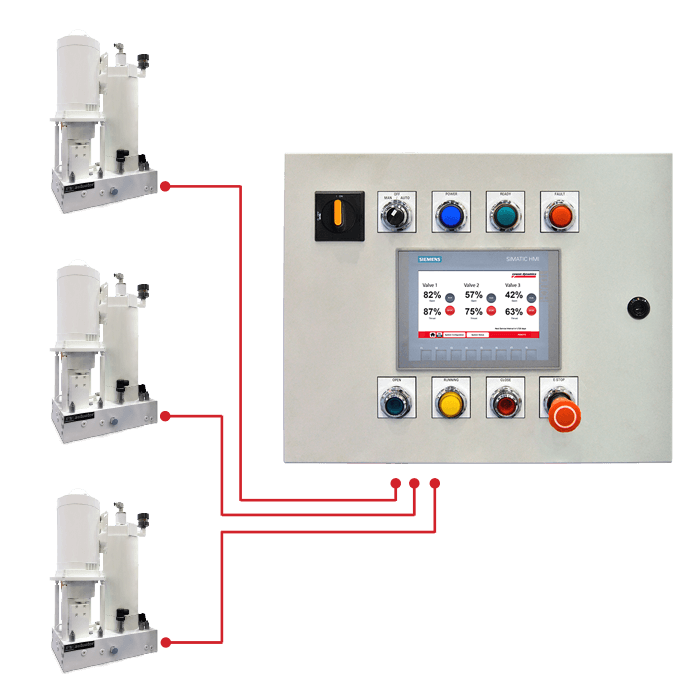

The control panel can be mounted directly to the manifold block or installed remotely to run multiple units from a single control panel This self-contained actuator can be installed either vertically or horizontally and has no external piping.

Operate Your E2H Remotely Using Our Remote Panel Option

- The control panel on the electro-hydraulic actuator can be mounted remotely and control multiple valves.

- It’s ideal for hazardous area locations.

- It gives you the flexibility to mount the control panel in a safe zone thereby providing a significant cost saving.

- Access valve performance data for multiple valves from one control panel.

- Designed to suit your installation.

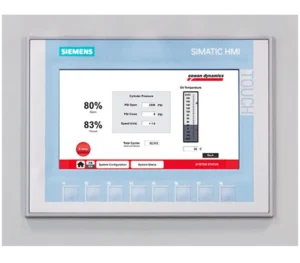

Main Panel: The E2H electro-hydraulic actuator control panel comes standard with touch screen* for quick setup and easy operation. The panel can be mounted remotely or on your E2H.

In addition, you can operate your E2H locally using the physical buttons on the front of the panel.

Status Screen: The E2H status screen gives you a quick overview of your system status. Available from the touch screen* or via Ethernet.

Remote Screen: Operate your E2HR remotely using one of the communication protocols below.