FCS Series

Air-Spring Fail-Safe Systems

Safe. Effective. Reliable. Air-Spring Fail-Safe Systems for Mission-Critical Close/Open Valve Applications.

Air-Spring Fail-Safe Systems

Cowan Dynamics air-spring systems provide a reliable solution for large or high-pressure valve applications in which conventional spring-return cylinders are not a mechanically or economically viable option. Designed to trigger a fail-open, fail-close or fail-last condition in the event of loss of power, air supply, or both; fail-safe systems prevent unwanted system conditions from occurring during emergency situations.

Each fail-safe system is engineered to meet your site-specific process control requirements and operating challenges

Worry-Free:

Automated, fully integrated control elements ensure fail-safe protection with little or no maintenance

Reliable:

Fully enclosed control panels withstand the harshest operating or environmental conditions

Secure:

Panels can be padlocked to prevent unauthorized access

Cost-Effective:

World-renowned for their durability, Cowan systems are built to provide years of service

Download brochure

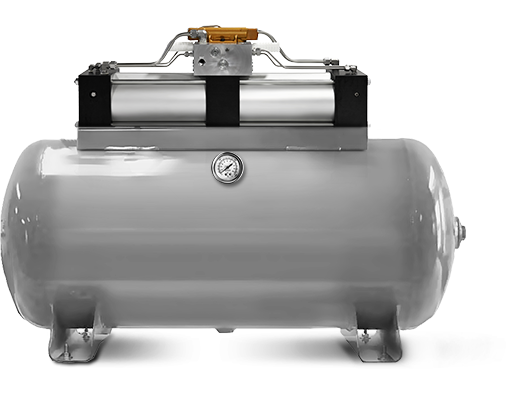

Basic Fail-Safe Systems

Basic air-spring systems include an air tank and pneumatic controls sized and configured to meet specific application needs.

- Air tanks are ASME stamped and available with 20 to 5,000 gallon capacity

- Components are selected based on site-specific requirements: available air pressure, temperature and pressure range, cycle time, number of actuators, number of strokes, etc.

- For harsh environments, the control instruments can be housed in a protective enclosure

Boosted Fail-Safe Systems

Consisting of a basic system to which a Cowan A2A pneumatic booster is added, these systems are designed for applications in which the available air pressure is too low and where space for additional air tanks is limited.

- Cowan’s A2A pneumatic boosters intensify the pressure of the available air supply without the need for additional mechanical or electrical input

- Available in 2:1, 3:1, or 4:1 ratios

- Do More With Less: Smaller footprint of the entire fail-safe system allows users to reduce the actuator size, by increasing the operating pressure

- 785 lbs

- 400 Gallon Tank

- 30″ x 30″ Footprint

- 20″ Bore Pneumatic Valve Actuator

up to85% Smaller

up to45% Lighter

up to40% Cost Savings

- 430 lbs

- 60 Gallon Tank

- 20″ x 20″ Footprint

- 16″ Bore Pneumatic Valve Actuator