Aumenta la eficiencia de las celdas de flotación con la avanzada tecnología patentada de Cowan para #actuadores de válvula tipo dardo. Experimenta la precisión en el procesamiento de minerales en tu celda de flotación. La serie AT está equipada con un transductor integrado que elimina la necesidad de brazos de enlace tradicionales que suelen romperse. Ver por LinkedIn: https://www.linkedin.com/feed/update/urn:li:activity:7126200101265371136 #Tecnología #ProcesamientoDeMinerales #Innovación #valvulas #mineria #mineriachile #mineriaperu #flotation

Cowan Connection

Latest News from Cowan Dynamics

Cowan Dynamics’ presence at the IMARC is crucial forvalve automation in the mining industry

Cowan Dynamics' presence at the International Mining and Resources Conference (IMARC) in beautiful Sydney, Australia, is crucial for staying at the forefront of valve automation in the #mining industry. Aymen Ghorbal, Executive VP, is joining 500+ experts and 470+ leading companies at the most innovative mining event of 2023.🤝👨💼 👷♀️ We’re meeting with our valued partners and customers to share insights and keep our customers informed on the latest developments in valve automation in the mining industry. #valveautomation #valves #actuators #miningindustry #miningnews #imarc #imarc2023

🚢 Our Latest Shipment – Pneumatic Diaphragm Actuator CDA Series

When it comes to harnessing the force of pressured fluids to drive your #actuators, there's virtually no actuator we can not provide. We're thrilled to showcase our latest Pneumatic Diaphragm Actuator CDA Series shipment, all set to supercharge your control applications! At Cowan Dynamics, customization is our forte. We provide actuators equipped with precisely matched controls to ensure seamless integration with your systems. Your unique needs, our tailored solutions! Ready to elevate your actuator game? Contact us today to explore how the CDA Series can transform your operations. #valves #actuators #valveautomation

Our AT Series Pneumatic Control Linear Actuators en Route to a Global Copper Giant! 🚀

Exciting times at Cowan Dynamics Inc! Our latest shipment of our Series AT Pneumatic Control Linear Actuators is now on its journey to one of the world's largest copper deposits. These high-performance actuators are designed to play a critical role in level control of the copper flotation cells, ensuring precision, reliability, and efficiency. ⚙️ Discover the Series AT and chat 💬 online with an Application Engineer or call us at 📞 +1-514-341-3415.

Pneumatic Linear Actuators for Speed Control on Check Valves

Our latest Pneumatic Linear Actuators shipment is all set to revolutionize fluid control. 🌬️ These actuators are en route to be installed on check valves, where they'll serve as speed controls, delicately regulating valve openings to prevent abrupt closures that could lead to water hammer. Designed to excel in applications with high flow fluctuations, our A Series double-acting pneumatic valve actuators promise enhanced efficiency and safety, ensuring seamless operations even in dynamic conditions. #FluidControl #Innovation #IndustrialAutomation #Efficiency #SafetyFirst #ManufacturingExcellence #ValveActuators #miningindustry #mining #oilgas #oilandgas #oilgasindustry

Electro-Hydraulic Actuator Powers Feedwater Pump Minimum Flow Control Valve

Installation Spotlight: Empowering Feedwater Pump Minimum Flow Control Valve with Cowan's E2H Electro-Hydraulic Valve Actuator! Say “Goodbye” to maintenance downtime and embrace uninterrupted excellence with our remarkable E2H Electro-Hydraulic Actuator. With the E2H, reliability meets redundancy, ensuring seamless operations through an array of cutting-edge features: ✅ 100% Redundant System: Dual Motors, Pumps, and PLCs✅ Hydraulic Manual-Override: Total Control in Your Hands✅ Single Acting Spring Return: Swift Reaction for Failures✅ Visual Indication: Transparency at a Glance At Cowan Dynamics, we're committed to pioneering solutions that drive efficiency and reliability. The E2H Electro-Hydraulic Actuator is a testament to our dedication to delivering unparalleled performance in...

Unparalleled Support from Cowan Dynamics

Testimonial We have been specifying Cowan pneumatic and electro-hydraulic actuators for over ten years, and throughout this period, Cowan has supported us all the way, from supplying timely quotes, providing quality products, and offering field support. As an example, we used 12 of their electro-hydraulic actuators on a project in the Middle East. The actuators had a complex specification according to the customer's requirements. The actuators have been operational for over 6 years, but Cowan has supported us through the operational process. For example, the user wanted to modify the control system to install a UPS system. Cowan visited the site and made the required modifications to the actuators according to the customer's requirements. All in all, great support from Cowan. ADRIAN...

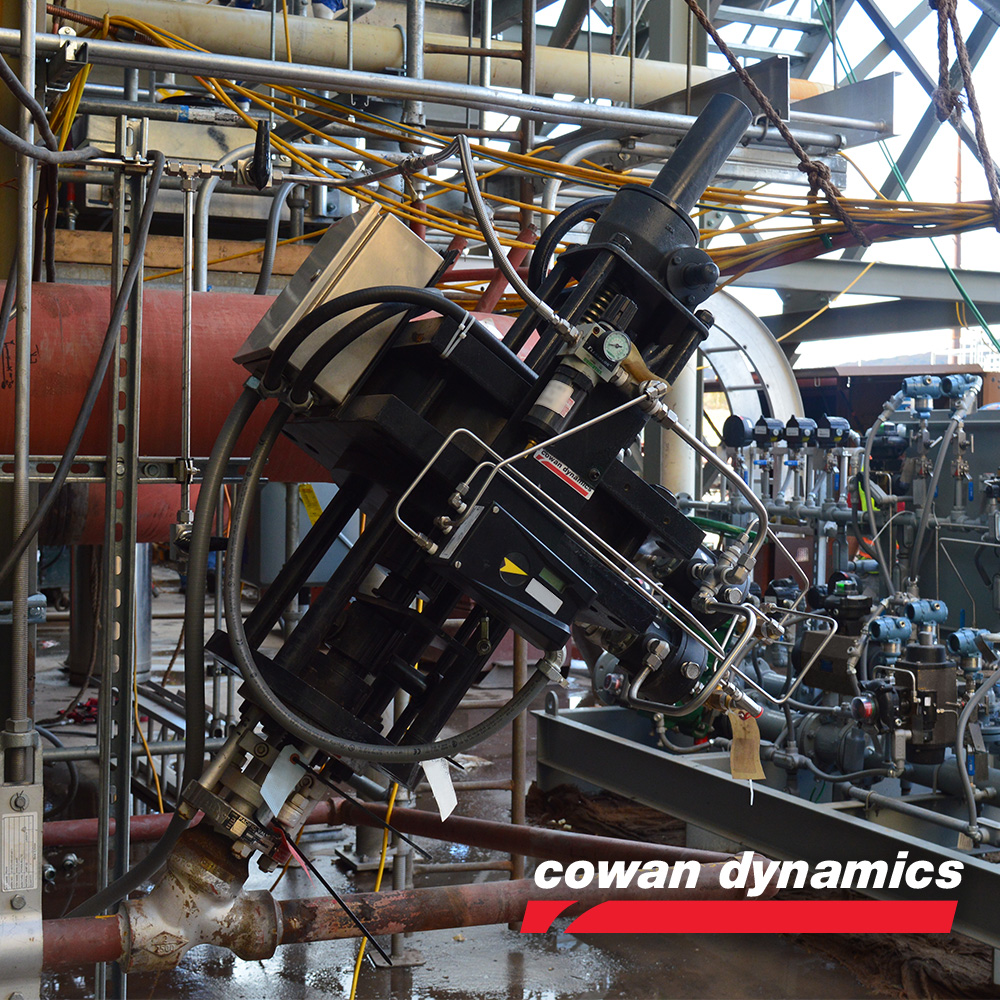

Pneumatic Modulating Control Valve Actuator Installed on a 60” Damper Valve

In this Installation Spotlight, Cowan Dynamics' Series AT, Pneumatic Modulating Control Valve Actuator, was installed on a 60” Damper Valve. The Series AT provides precise and accurate control over the damper valve's position with an impressive 30-second stroke time. ✅ Discover the Series AT and chat 💬 online with an Application Engineer or call us at 📞 +1-514-341-3415. #valves #actuators #valveautomation #dampervalve #mining #miningindustry #processcontrol #processautomation #miningnews

Cowan Dynamics Powers Largest Tsunami Test Rig in The World

Testimonal First of all, please accept my warmest thanks for this great engineering masterpiece! I am extremely happy to report that, once completed, this would be the largest automated tsunami gate in the world! And, what is even more important, respecting the strict technical parameters such as the opening time (below 1 second – 0.75 seconds – WOW! J) colleagues in Universities in Japan, Germany and Netherlands – they were impressed! Encore une fois, GROS merci! Ioan NISTOR, PhD, ing., F.CSCE, F.EICProfesseur / ProfessorGénie Civil | Civil Engineering

We are pleased to announce that we have partnered with Instruvalve Perú

We are pleased to announce that we have partnered with Instruvalve Perú. Instruvalve Perú is appointed as Cowan Dynamics Inc exclusive distributor servicing Perú. Instruvalve Peru, a national company with 8 years of experience in the market, provides reliable solutions in the area of Automation, Process Control and Fluid Management. We welcome Instruvalve Peru as our Regional Business Partner!

We are pleased to announce that we have partnered with company ASTROTECH EQUIPMENTS PRIVATE LIMITED

We are pleased to announce that we have partnered with company ASTROTECH EQUIPMENTS PRIVATE LIMITED. ASTROTECH is appointed as Cowan Dynamics Inc exclusive distributor servicing the territories of India, Bangladesh, Sri Lanka, Nepal & Bhutan. With a strong passion in control valves, ASTROTECH Equipments has honed its skills in marketing and servicing all types of control valves, we are confident that our partnership will provide our customers with an outstanding quality and exceptional customer service. Welcome ASTROTECH as our Regional Business Partner!

El actuador E2H-ESD es la más reciente adición a la línea de actuadores electrohidráulicos

El actuador E2H-ESD es la más reciente adición a la línea de #actuadoreselectrohidráulicos de Cowan Dynamics, diseñada -específicamente- para la automatización de #válvulas de cierre de emergencia (ESD). Lea el artículo de Tecnología Minera : https://bit.ly/3RaL015

Emergency Shutdown (ESD) Valve Automation with Cowan’s E2H-ESD Actuator

Read the "Emergency Shutdown (ESD) Valve Automation with Cowan’s E2H-ESD Actuator" article featured in Fluid Handling Pro - Fluid Handling Innovationswebsite. The E2H-ESD is critical for #pipelinesafety that requires fast, safe, and reliable failure conditions on the loss of power and/or ESD signals in the #oilgasindustry. Learn more: https://bit.ly/3NPYyMN

No application is too large or too small!

No application is too large or too small. We engineer our valve actuators to meet our customer's specifications. This small Series AS Compact model has a 10" bore with a 2.75" stroke. Compare this to our large Series AS tandem 32" bore with a 12" stroke. Learn more about our spring-return pneumatic #actuators: https://bit.ly/3OAfuI3

Instruvalve Chile at EXPONOR CHILE

Come visit us, Cowan Dynamics Inc, we are with Instruvalve Chile at EXPONOR CHILE in the USA pavilion, stand 180.

Duke T. Tran PEng MBA visiting at Velan Inc.

This Month we had the visit of Duc (Duke) T. Tran PEng MBA at Velan Inc.During an inspection of our latest E2H90 Electro-hydraulic units for rotary valves, he had the opportunity to see the latest addition to our Electro-hydraulic family, the E2H-ESD. The E2H-ESD is designed for emergency shutdown #valves and successfully finished a 26,000 cycle performance test. Thank you for the visit, Duke!! Learn more about the E2H-ESD: https://lnkd.in/ey346QbG

Trade fair at ISA Calgary Section

Thank you to our valued business partner, Summit Valve and Controls! It was a successful trade fair at ISA Calgary Section.

Rush order of valve actuator for critical plant shut down at an oil and gas facility

Going the extra mile for our customers is always our priority. Rush order for a critical plant shut down at an oil and gas facility in Western Canada. The transducer supplier severely delayed the shipping however our excellent engineering team found a solution within our series AT, Pneumatic Modulating Control Valve Actuator, and redesigned the already made actuator and built it in one day!

E2H90 Valve Actuator Shipment for Emergency Shutdown Trunnion Ball Valves

Look at the latest shipment of our Electro-Hydraulic actuators for on/off rotary valves, E2H90. These units are getting ready to be installed in emergency shut down trunnion ball valves. These actuators have a rated torque of 1.3 million lbs-in, 8 to 60 secs adjustable fail time, position feedback via 4-20ma HART, Explosion-proof rated, and a safety integrity level of 2.

Series A Valve Actuator Installation for Flotation Cell Maintenance in Mexico Gold Mine

Another happy customer! These actuators from our series A valve actuators, automated and tested by Cowan have just been installed at a gold mine in the south of Mexico as part of bypass systems for flotation cells maintenance. Thank you to our partner Instruvalve for all the great support.

Featured Valve Automation Actuators

A Series Feature

Designed and engineered for severe-service applications, the A Series bore sizes range from 4” to a whopping 42” diameter. We also offer a wide range of automation options.

AS Series Feature

Next-generation “compact” model provides a shorter and lighter canister for installations where space is a premium.

ML Series Feature

Our ML Series Double-Acting Hydraulic Valve Actuators are designed to suit a wide range of applications; from commodity to severe-service extremes.